|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

The Main features of this machine: |

|

The main body of this machine is made of enhanced structure, so it will have less deformation during the forging process. |

|

There is more space between bolster plate and ram; therefore, robots can be installed on this machine for automatic operation.

|

|

The movement of the ram can be stopped efficiently by the braking system, so each stroke length and force can remain almost equivalent.

|

|

In order to maintain steady movement of the ram, the lubrication system for main screw uses both grease and lubricant mixed together.

|

|

Friction plates on the flywheel and linings on the braking device can be directly changed without removing the entire set of friction wheel.

|

|

Most of equipments on this machine are controlled by pneumatic pressure, so it has higher stability.

|

|

Two consecutive strokes are available, and each independent stroke speed and length can be altered separately.

|

|

This machine equips with several safety measures for die inspection, maintenance, and adjustment.

|

|

This machine also equips with following devices to meet operational needs:

|

|

[Load monitor: it is convenient to use this to inspect the forging force and to see the operation is working normally.

|

|

[Speed controller: with this device, the forging force can be easily adjusted.

|

|

Touch monitor: it is used to display and set the stroke speed and other functions. |

|

|

|

|

|

|

|

|

|

|

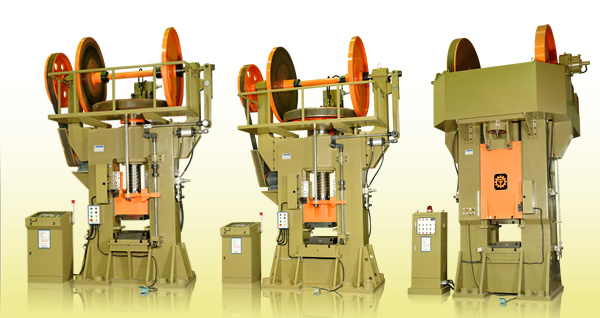

Screw press features and applications: |

Basically, the power of this type of machine is generated by screw mechanism which also leads the ram up and down to create press force needed for forging. This machine is generally used on warm and hot forging, cold forging for thin pieces, and precision correction after casting or drop forging. Right now a lot of companies in Europe, Japan and other countries are adopting this type of machines for precision forging.

This machine type HDFP is using friction wheels and friction as driving force to proceed forging works. Therefore, it is also called “Friction Screw Press”. |

|

|

|

|

|

|

|

|

|

There are several advantages for using this machine: |

|

There is no lower dead point, so the ram will not be jammed because the forged piece is oversized or the temperature is too low. |

|

The contact time between the forged piece and dies is very brief; therefore, it can reduce the wear of the dies. |

|

In order to achieve ideal accuracy and tolerance, it is able to forge the same piece by using two consecutive strokes with different forging forces.

|

|

It is easy to operate and no experienced operator is required. |

|

|

|

|

|

|

|

|

|

|

Applicable Forging Products: |

|

It is suitable for different materials: steel, copper, aluminum, titanium alloy, magnesium alloy, copper alloy, stainless steel, and carbon brick. |

|

Parts for sports equipment: golf club head, connecting rods, pulleys, and so on.

|

|

Engine internal valves and pistons for automobile, motorcycle, boat, and other kind of transport vehicles.

|

|

Transfer parts, connecting rods and starting bars for bicycle, electric car, and other vehicles.

|

|

High pressure valves, switches, terminals and joints used for oxygen, air conditioning, refrigerating, gas, pneumatic, and hydraulic equipments.

|

|

House hardware and bathroom accessories: door lock, towel holder, fence, stair rail, and so on.

|

|

Thin metal products: badge, name plate, door lock panel, and so on.

|

|

Tableware: knife, fork, and spoon.

|

|

Watchcase and clock case.

|

|

Diverse tools and hardware. |

|

|

|

|

|

|

|

|

|

|

|

|